Cobalt Base Alloy e manganga ho apara le ho bola

Tlhaloso

KF-3321 ke phofo ea alloy e thehiloeng ho cobalt e nang le khanyetso e ntle ea ho apara le ho hanyetsa mocheso o phahameng oa oxidation.E entsoe ka cobalt, chromium, tungsten, nickel, silicon, le carbon, hape e ka 'na ea e-ba le lisebelisoa tse nyenyane tsa aluminium, niobium, tantalum le lisebelisoa tse ling tsa alloy.

Thepa ea phofo

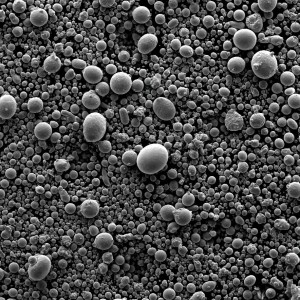

Boholo ba Karolo:KF-3321 e na le mefuta e fapaneng ea boholo ba likaroloana tsa -140 ho +325 mesh, e etsang hore e tšoanelehe bakeng sa lits'ebetso tse fapaneng moo ho hlokahalang boholo ba likaroloana.

Mofuta:KF-3321 ke khase atomized phofo, e bolelang hore e hlahisoa ka ho qhibiliha motsoako ebe o atomizing ka khase e phahameng ea khatello.Sena se etsa hore ho be le sebopeho sa phofo se chitja, se fanang ka phallo e ntle le boima ba ho paka.

Moetso:KF-3321 ke phofo ea alloy e thehiloeng ho cobalt e nang le karolo e phahameng ea cobalt, e fanang ka ho hanyetsa ho apara hantle.Ho eketsoa ha chromium le tungsten ho ntlafatsa ho hanyetsa ha eona ho apara le ho hanyetsa mocheso o phahameng oa oxidation.Nickel, silicon, le carbon li fana ka matla a eketsehileng le ho hanyetsa ha kutu ho motsoako.

Kopo

KF-3321 ke phofo ea alloy e feto-fetohang e ka sebelisoang liindastering tse fapaneng bakeng sa lits'ebetso tse hlokang khanyetso e ntle ea ho roala le ho hanyetsa mocheso o phahameng oa oxidation.Lisebelisoa tse ling tse tloaelehileng li kenyelletsa:

Li-valve tsa khatello e phahameng ea mocheso:KF-3321 e hanyetsanang le mocheso o phahameng oa oxidation e etsa hore e be thepa e loketseng bakeng sa li-valve tsa khatello e phahameng ea mocheso.

Ho bona meno:KF-3321's wear resistance and toughness e etsa hore e loketse ho sebelisoa ka meno a sakha, a hlokang thepa e thata e ka mamellang khatello ea maikutlo le khatello ea ho itšeha.

Li-screws tsa extrusion:KF-3321's wear resistance and high-temperature oxidation resistance e etsa hore e be khetho e ntle ea ho sebelisoa ka li-screws tsa extrusion, tse hlokang thepa e ka mamellang mocheso o phahameng le likhatello tsa ts'ebetso ea extrusion.

E tšoana le St12:KF-3321 e na le thepa e tšoanang le ea St12, tšepe e tlaase ea carbon e atisang ho sebelisoa indastering ea likoloi.Leha ho le joalo, KF-3321 e na le khanyetso e ntle haholo ea ho roala le ho hanyetsa mocheso o phahameng oa oxidation ho feta St12, e leng se etsang hore e be khetho e phahameng bakeng sa likopo tse hlokang ho hanyetsa ho apara haholo le botsitso ba mocheso o phahameng.

Ka kakaretso, KF-3321 ke phofo ea alloy e sebetsang hantle e fanang ka khanyetso e ntle ea ho roala le ho hanyetsa mocheso o phahameng oa oxidation.Thepa ea eona e fapaneng e etsa hore e tšoanelehe bakeng sa mefuta e mengata ea likopo liindastering tse fapaneng.

Lihlahisoa tse tšoanang

| Brand | Lebitso la Sehlahiswa | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-331 | CoCrMoSi | 340 | 66/3002 | CO109 / 1247 | T400 | |

| KF-333 | CoCrMoSi | 342 | 68/3001/4800 | CO111 / 1248 | T800 | |

| KF-332 | CoCrWCNiSi | |||||

| KF-3321 | CoCrWCNiSi | |||||

| KF-3322 | CoCrWCNiSi | E tšoana le 344 | 4060 | CO106 1256 | 6 46 | |

| KF-3323 | CoCrWCNiSi | |||||

| KF-3324 | CoCrWCNiSi | 344 | 45 x40 | CO105 / CO285 | 90 | |

| KF-3325 | CoCrWCNiSi |

Tlhaloso

| Brand | Lebitso la Sehlahiswa | Khemistri (wt%) | Ho thatafala | Mocheso | Thepa & Tšebeliso | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | W | C | Ni | Si | B | Mo | Co | |||||

| KF-331 | CoCrMoSi | 8 | 2.6 | 28 | Bal. | HRC 54 | ≤840ºC | •Apara khanyetso, khanyetso ea mengoapo •Ho hanyetsa ho bola | ||||

| KF-333 | CoCrMoSi | 17.5 | 3.4 | 35 | Bal. | HRC53 | ≤840ºC | •Apara khanyetso, khanyetso ea mengoapo •Ho hanyetsa ho bola | ||||

| KF-332 | CoCrWCNiSi | 25 | 7.5 | 0.8 | 10 | 1 | Bal. | HRC 30 | ≤840ºC | •Setulo sa valve •Ho jara •Lehare •E tšoana le St1 | ||

| KF-3321 | CoCrWCNiSi | 30 | 4 | 1.5 | 3 | 1.4 | 4 | Bal. | HRC45 | ≤840ºC | •PTA, APS, HVOF, laser cladding, spherical • Li-valve tsa khatello e phahameng ea mocheso, meno a sakha, li-screws tsa extrusion •E tšoana le St12 | |

| KF-3322 | CoCrWCNiSi | 30 | 4.5 | 1 | 3 | 1.4 | Bal. | HRC 40 | ≤840ºC | •PTA, APS, HVOF, laser cladding, spherical • Li-valve tsa enjine, boleng ba khatello e phahameng ea mocheso, likhaba tsa enjine ea turbo •E tšoana le St6 • Ho hanyetsa ho apara hantle ha mocheso o phahameng | ||

| KF-3323 | CoCrWCNiSi | 28 | 0.25 | 3 | 1 | 5.5 | Bal. | HRC55 | ≤840ºC | • Li-blades tsa turbine •Li-valve tsa metsi •Setulo sa valve | ||

| KF-3324 | CoCrWCNiSi | 25.5 | 7.5 | 0.5 | 10.5 | 1 | Bal. | HRC 30 | ≤840ºC | • Extrusion hlobo •Mahare a turbine ea khase | ||

| KF-3325 | CoCrWCNiSi | 21.0 | 5 | 0.1 | 1 | 1.6 | 2.4 | Bal. | HRC50 | ≤840ºC | •PTA, APS, HVOF, laser cladding, spherical • Ho hanyetsa mocheso o phahameng oa ho apara • Li-valve tsa lithuthuthu •Ho iphapanyetsa | |