Multi-function Composite cladding powder

Tlhaloso

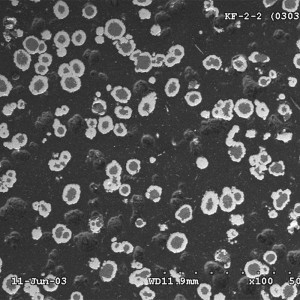

Nickel e koahetsoeng ka graphite composite powder ke phofo e kopantsoeng e nang le likaroloana tsa graphite e le motheo oa eona le tšepe ea tšepe e le seaparo sa eona sa ka ntle, se nang le lubrication e ntle le ho hanyetsa ho bola.Kamora ho fafatsa ka mocheso, thepa e ka theha matla a phahameng, ho hanyetsa oxidation, ho hanyetsa mocheso oa mocheso le coefficient e tlase ea likhohlano.

Tlhaloso

| Brand | Lebitso la Sehlahiswa | Khemistri (wt%) | Ho thatafala | Mocheso | Thepa & Tšebeliso | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | KeAl82/18 | 20 | Bal. | HRC 20 | ≤800ºC | •Lelakabe, APS, Max.mocheso o sebetsang 650°C. • E hanyetsana le oxidation e teteaneng ebile e sebetsa ka thata. | ||||||||

| KF-6 | KeAl95/5 | 5 | Bal. | HRC 20 | ≤800ºC | •Flame, APS, HVOF, Max.mocheso o sebetsang 800°C • E hanyetsana le oxidation e teteaneng ebile e sebetsa ka thata | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤ 500ºC | • E sebelisoa bakeng sa likarolo tsa ho tiisa tse suthang le mehele e tiisang e silang • E ka sebelisoa e le lisebelisoa tse fokolang tsa likhohlano | ||||||||

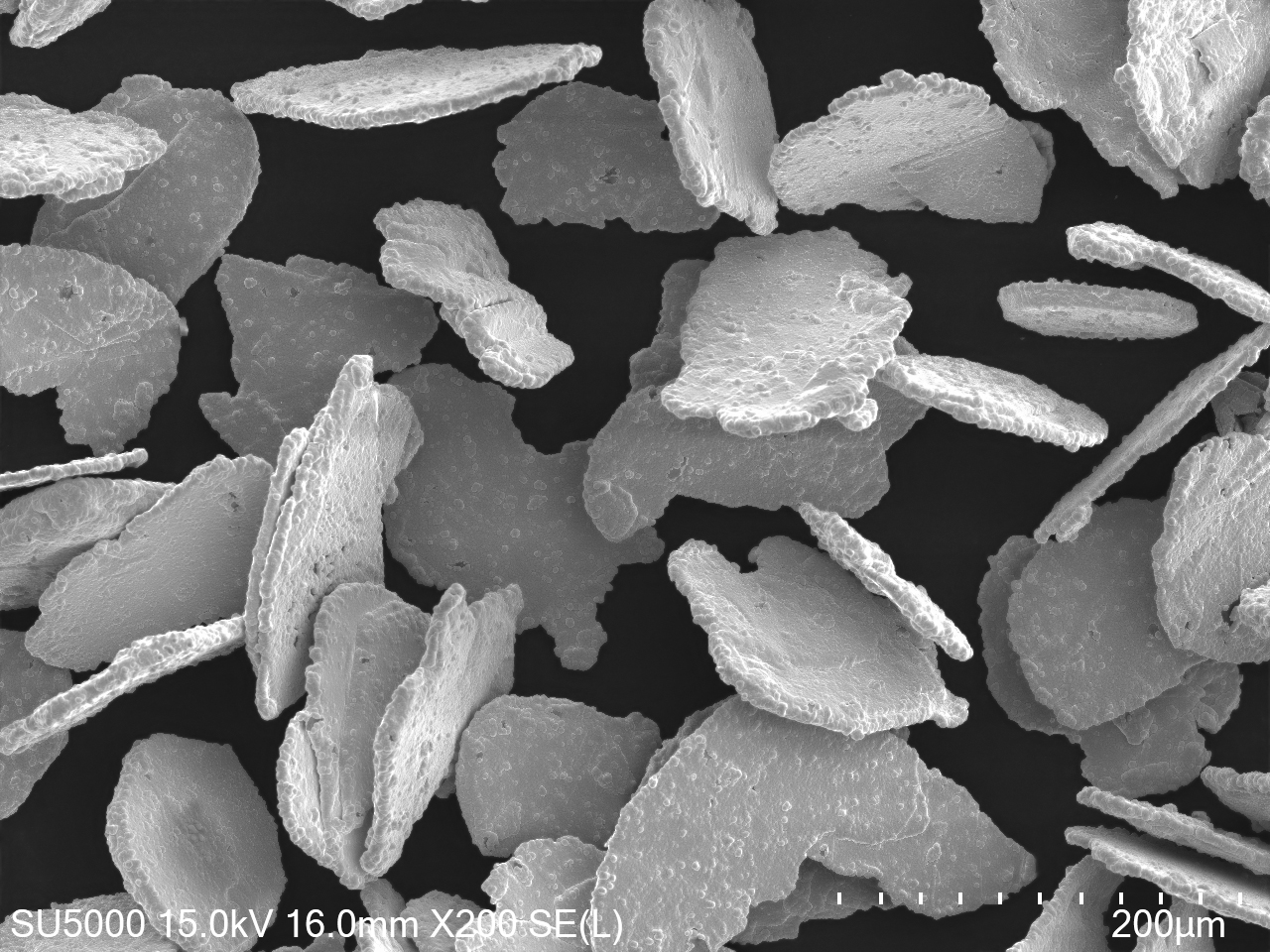

| KF-21T | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | •Lelakabe, Max.mocheso o sebetsang 480 ° C 1. Ho roala lisebelisoa tsa turbo compressor • E sebetsa ho alloy ea nickel le likarolo tsa tšepe • Lihlahisoa tse nang le li-graphite tse phahameng li loketse likarolo tsa titanium ntle le bohale • Likahare tse phahameng tsa graphite li tla ntlafatsa ts'ebetso ea lubrication •Likahare tse phahameng tsa nickel li tla ntlafatsa ho hanyetsa khoholeho • Lihlahisoa tse tšoanang li fapane ka lebaka la litlhaloso tse fapaneng tsa OEM | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

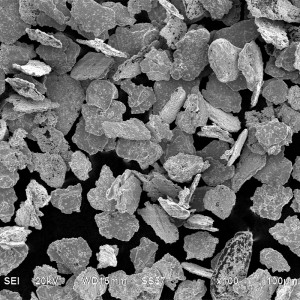

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤800ºC | •Flame,APS, e sa tloaelehang • E ka sebelisoa ho qhibilihisa crucible, terminal e koalang holim'a metsi le bokaholimo ba hlobo e le lera le sireletsang | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤400ºC | •Flame,APS, e sa tloaelehang •Ho hana hamore, khoholeho ea mobu, ho khojoa le ho khoroha ha ho thella | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤400ºC | • Lelakabe, le sa tloaelehang •Ho hana hamore, khoholeho ea mobu, ho khojoa le ho khoroha ha ho thella | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤ 550ºC | •Flame, APS, e sa tloaelehang, Max.mocheso o sebetsang 815°C. • Apara thepa e thibang, e ka sebelisetsoang ho lokisa marake a tanka | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤800ºC | •Lelakabe, APS, Max.mocheso o sebetsang 980°C. • Ho fafatsa ka plasma ka ho itlama | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, e sa tloaelehang, Max.mocheso o sebetsang 980°C. • E sebetsa ho lokisoa ha mocheso o phahameng oa ho kopanya mocheso kapa likarolo tsa ho roala / tse sa sebetsoeng hantle | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | • Self bonding, coat e tloaelehileng e thata bakeng sa ho kenya kopo •E thata, e nang le khanyetso e ntle ea kutu le ts'ebetso ea ts'ebetso • E sebelisoa bakeng sa likarolo tsa mochine, setulo se nang le setulo le valve | |||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame,APS, irregular, Max.mocheso o sebetsang 650°C. •Bakeng sa litiiso tse silang, ho kenyeletsoa likarolo tsa tiiso tse suthehang, masale a tiisitsoeng a silang, lisebelisoa tse tlase tse hohlang. | ||||||||||||