Ni-Graphite Cladding phofo e nang le conductivity ea motlakase

Tlhaloso

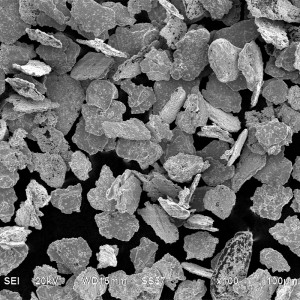

Ni-Graphite Cladding powder ke sesebelisoa se ikhethileng haholo se etselitsoeng ho fana ka ts'ebetso e holimo lits'ebetsong tse hlokang indasteri.Phofo ena e ncha e na le lik'hemik'hale tse nang le nickel e ngata le graphite, e leng se etsang hore e be khetho e nepahetseng bakeng sa ho roala lisebelisoa tsa turbo compressors, nickel alloy le likarolo tsa tšepe.

E 'ngoe ea likarolo tsa bohlokoa tsa phofo ea Ni-Graphite Cladding ke litaba tsa eona tse phahameng tsa graphite.Tšobotsi ena e ntlafatsa ts'ebetso ea lubrication ea phofo, e etsa hore e be khetho e tsebahalang bakeng sa tšebeliso ea likarolo tsa titanium tse se nang moeli.Ho phaella moo, lihlahisoa tse phahameng tsa nickel tsa phofo li ntlafatsa ho hanyetsa khoholeho ea mobu, ho netefatsa hore e fana ka ts'ebetso e nepahetseng libakeng tse thata tsa indasteri.

Ni-Graphite Cladding powder e fumaneha ka mekhoa e 'meli e fapaneng: KF-21 Ni-Graphite 75/25 le KF-22 Ni-Graphite 60/40.Mefuta ena e 'meli e na le likarohano tse fapaneng tsa nickel le graphite, e leng se etsang hore e tšoanele mefuta e fapaneng ea lits'ebetso tsa indasteri.Mohlala, KF-21 Ni-Graphite 75/25 e na le litaba tsa nickel tse phahameng, tse etsang hore e be e loketseng ho sebelisoa lits'ebetsong tse hlokang khanyetso e phahameng ea khoholeho.

Ntle le litšoaneleho tsa eona tse phahameng tsa ts'ebetso, phofo ea Ni-Graphite Cladding e boetse e na le mefuta e mengata haholo.E ka sebelisoa lits'ebetsong tse fapaneng tsa indasteri, ho kenyeletsoa li-compressor tsa turbo, alloy ea nickel le likarolo tsa tšepe.Ho feta moo, ho hanyetsa lelakabe la eona le mocheso o phahameng oa ho sebetsa oa 480 ° C ho etsa hore e be khetho e tšepahalang bakeng sa ho sebelisoa lits'ebetsong tse phahameng tsa mocheso.

Ha ho tluoa tabeng ea ho khetha phofo e nepahetseng ea Ni-Graphite Cladding bakeng sa kopo ea hau ea indasteri, ho bohlokoa ho nahana ka lintlha tse khethehileng tsa OEM tsa thepa ea hau.KF-21 e tšoana le AMPERIT 205, METCO/AMDRY 307NS, PRAXAIR NI-114, le PAC 138, ha KF-22 e tšoana le AMPERIT 200 le Durabrade 2211.

Qetellong, phofo ea Ni-Graphite Cladding ke thepa e khethehileng haholo e fanang ka ts'ebetso e phahameng ho likopo tse hlokahalang tsa indasteri.Likahare tsa eona tse phahameng tsa graphite le nickel e phahameng li e etsa khetho e nepahetseng bakeng sa ho roala thepa ea li-turbo compressors, alloy ea nickel le likarolo tsa tšepe.Ka ho feto-fetoha ha eona, ho hanyetsa lelakabe, le mocheso o phahameng oa ts'ebetso, phofo ea Ni-Graphite Cladding ke khetho e ka tšeptjoang bakeng sa mefuta e mengata ea lisebelisoa tsa indasteri.

Lihlahisoa tse tšoanang

| Brand | Lebitso la Sehlahiswa | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-21T/R | Ni-Graphite 75/25 | 205 | 307NS | NI-114 | 138 | |

| KF-22T/R | Ni-Graphite 60/40 | 200 | Durabrade 2211 |

Tlhaloso

| Brand | Lebitso la Sehlahiswa | Khemistri (wt%) | Ho thatafala | Mocheso | Thepa & Tšebeliso | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | KeAl82/18 | 20 | Bal. | HRC 20 | ≤800ºC | •Lelakabe, APS, Max.mocheso o sebetsang 650°C. • E hanyetsana le oxidation e teteaneng ebile e sebetsa ka thata. | ||||||||

| KF-6 | KeAl95/5 | 5 | Bal. | HRC 20 | ≤800ºC | •Flame, APS, HVOF, Max.mocheso o sebetsang 800°C • E hanyetsana le oxidation e teteaneng ebile e sebetsa ka thata | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤ 500ºC | • E sebelisoa bakeng sa likarolo tsa ho tiisa tse suthang le mehele e tiisang e silang • E ka sebelisoa e le lisebelisoa tse fokolang tsa likhohlano | ||||||||

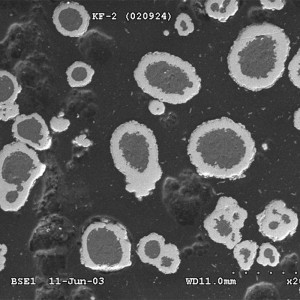

| KF-21T | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | •Lelakabe, Max.mocheso o sebetsang 480 ° C 1. Ho roala lisebelisoa tsa turbo compressor • E sebetsa ho alloy ea nickel le likarolo tsa tšepe • Lihlahisoa tse nang le li-graphite tse phahameng li loketse likarolo tsa titanium ntle le bohale • Likahare tse phahameng tsa graphite li tla ntlafatsa ts'ebetso ea lubrication •Likahare tse phahameng tsa nickel li tla ntlafatsa ho hanyetsa khoholeho • Lihlahisoa tse tšoanang li fapane ka lebaka la litlhaloso tse fapaneng tsa OEM | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤800ºC | •Flame,APS, e sa tloaelehang • E ka sebelisoa ho qhibilihisa crucible, terminal e koalang holim'a metsi le bokaholimo ba hlobo e le lera le sireletsang | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤400ºC | •Flame,APS, e sa tloaelehang •Ho hana hamore, khoholeho ea mobu, ho khojoa le ho khoroha ha ho thella | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤400ºC | • Lelakabe, le sa tloaelehang •Ho hana hamore, khoholeho ea mobu, ho khojoa le ho khoroha ha ho thella | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤ 550ºC | •Flame, APS, e sa tloaelehang, Max.mocheso o sebetsang 815°C. • Apara thepa e thibang, e ka sebelisetsoang ho lokisa marake a tanka | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤800ºC | •Lelakabe, APS, Max.mocheso o sebetsang 980°C. • Ho fafatsa ka plasma ka ho itlama | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, e sa tloaelehang, Max.mocheso o sebetsang 980°C. • E sebetsa ho lokisoa ha mocheso o phahameng oa ho kopanya mocheso kapa likarolo tsa ho roala / tse sa sebetsoeng hantle | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | • Self bonding, coat e tloaelehileng e thata bakeng sa ho kenya kopo •E thata, e nang le khanyetso e ntle ea kutu le ts'ebetso ea ts'ebetso • E sebelisoa bakeng sa likarolo tsa mochine, setulo se nang le setulo le valve | |||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame,APS, irregular, Max.mocheso o sebetsang 650°C. •Bakeng sa litiiso tse silang, ho kenyeletsoa likarolo tsa tiiso tse suthehang, masale a tiisitsoeng a silang, lisebelisoa tse tlase tse hohlang. | ||||||||||||