Fektheri Bakeng sa phofo ea NiAl cladding

Thomo ea rona ke ho fa basebelisi ba rona ba ho qetela le bareki ka thepa ea boleng bo holimo le e nkehang habobebe ea dijithale bakeng sa Factory For NiAl cladding powder, Lab ea rona joale ke "National Lab of diesel engine turbo technology", 'me re na le sehlopha sa R&D se nang le boiphihlelo le liteko tse felletseng. setsing.

Thomo ea rona ke ho fa basebelisi ba rona ba ho qetela le bareki thepa ea boleng bo holimo le ea tlholisano ea dijithale bakeng saChina NiAl cladding phofo, Sepheo sa rona se latelang ke ho feta litebello tsa moreki e mong le e mong ka ho fana ka litšebeletso tse ntle tsa bareki, ho eketseha ha maemo le boleng bo boholo.Ka kakaretso, ntle le bareki ba rona ha re eo;ntle le bareki ba thabileng le ba khotsofetseng ka ho feletseng, re hlōleha.Re ntse re batla mabenkele a mangata, Drop ship.U lokela ho iteanya le rona haeba u khahloa ke thepa ea rona.Ke tšepa ho etsa khoebo le uena kaofela.Thomello ea boleng bo holimo le e potlakileng!

Tlhaloso

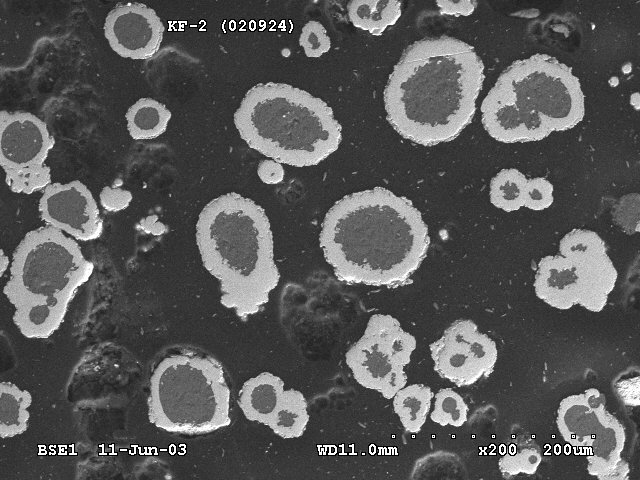

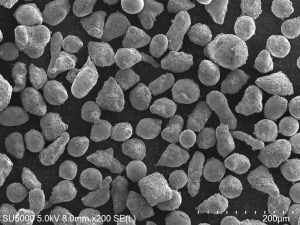

Re motlotlo ho hlahisa lihlahisoa tse peli tse thehiloeng ho phofo ea NiAl: KF-2 le KF-6.Lihlahisoa tsena tse peli li sebelisa litekanyo tse fapaneng tsa phofo ea NiAl mme li na le litšobotsi tse ikhethang le lits'ebetso.

KF-2 e sebelisa NiAl82/18, e nang le 82% Ni le 18% Al.Sehlahisoa sena se loketse lits'ebetso tse nang le mocheso o phahameng oa ho sebetsa oa 650°C.E fana ka lesela le letenya, le khonang ho sebetsa, le thibelang oxidation, 'me le sa senyehe le nang le thepa ea ho itlama.Kamehla ho na le karabelo e makatsang nakong ea ho fafatsa, e hlahisang matla a matle a matle ho feta thepa ea Ni5Al.KF-2 e loketse bakeng sa ho lokisa le ho etsa bocha machinable carbon steel le tšepe e sa jeng, hape e ka sebelisoa bakeng sa ho kopanya likarolo tsa lirafshoa le thepa e ka aparoang.

KF-6 e sebelisa NiAl95/5, e nang le 95% Ni le 5% Al.Sehlahisoa sena se loketse lits'ebetso tse nang le mocheso o phahameng oa 800 ° C 'me se ka sebelisoa ka mekhoa e fapaneng ea ho fafatsa joalo ka lelakabe, APS, le HVOF.E boetse e fana ka lesela le letenya, le machina, le thibelang oxidation, 'me le sa senyehe le nang le thepa ea ho itlama.Ka linako tsohle ho na le karabelo e makatsang nakong ea ho fafatsa, e bakang matla a matle a ho kopanya.KF-6 e ka boela ea sebelisoa bakeng sa ho lokisa le ho etsa botjha machinable carbon steel le tšepe e sa jeng, hammoho le likarolo tse tlamang tsa lirafshoa le thepa e ka aparoang.

Ka bokhutšoanyane, ka bobeli KF-2 le KF-6 ke lihlahisoa tse thehiloeng ho phofo ea NiAl tse fanang ka matla a matle a tlamahano le khanyetso ea ho roala.KF-2, e nang le karolo e tlase ea phofo ea NiAl (NiAl82/18), e loketse likopo tse nang le mocheso o phahameng oa ho sebetsa oa 650 ° C, ha KF-6, e nang le karolo e phahameng ea phofo ea NiAl (NiAl95/5), e ka sebetsana le mocheso o phahameng ho fihlela ho 800°C mme e ka sebelisoa ka mekhoa e fapaneng ea ho fafatsa.Lihlahisoa tsena ka bobeli li loketse bakeng sa ho lokisa le ho etsa botjha machinable carbon steel le tšepe e sa jeng, hammoho le ho kopanya likarolo tsa lirafshoa le thepa e ka aparoang.Khetho pakeng tsa KF-2 le KF-6 e itšetlehile ka litlhoko tse khethehileng tsa kopo le mocheso o phahameng oa ho sebetsa o hlokahalang.

Lihlahisoa tse tšoanang

| Brand | Lebitso la Sehlahiswa | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-2 | KeAl82/18 | 404NS | ||||

| KF-6 | KeAl95/5 | 282 | 956450NS | NI-109 | 906 |

Tlhaloso

| Brand | Lebitso la Sehlahiswa | Khemistri (wt%) | Ho thatafala | Mocheso | Thepa & Tšebeliso | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | KeAl82/18 | 20 | Bal. | HRC 20 | ≤800ºC | •Lelakabe, APS, Max.mocheso o sebetsang 650°C. • E hanyetsana le oxidation e teteaneng ebile e sebetsa ka thata. | ||||||||

| KF-6 | KeAl95/5 | 5 | Bal. | HRC 20 | ≤800ºC | •Flame, APS, HVOF, Max.mocheso o sebetsang 800°C • E hanyetsana le oxidation e teteaneng ebile e sebetsa ka thata | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤ 500ºC | • E sebelisoa bakeng sa likarolo tsa ho tiisa tse suthang le mehele e tiisang e silang • E ka sebelisoa e le lisebelisoa tse fokolang tsa likhohlano | ||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | •Lelakabe, Max.mocheso o sebetsang 480 ° C 1. Ho roala lisebelisoa tsa turbo compressor • E sebetsa ho alloy ea nickel le likarolo tsa tšepe • Lihlahisoa tse nang le li-graphite tse phahameng li loketse likarolo tsa titanium ntle le bohale • Likahare tse phahameng tsa graphite li tla ntlafatsa ts'ebetso ea lubrication •Likahare tse phahameng tsa nickel li tla ntlafatsa ho hanyetsa khoholeho • Lihlahisoa tse tšoanang li fapane ka lebaka la litlhaloso tse fapaneng tsa OEM | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤800ºC | •Flame,APS, e sa tloaelehang • E ka sebelisoa ho qhibilihisa crucible, terminal e koalang holim'a metsi le bokaholimo ba hlobo e le lera le sireletsang | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤400ºC | •Flame,APS, e sa tloaelehang •Ho hana hamore, khoholeho ea mobu, ho khojoa le ho khoroha ha ho thella | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤400ºC | • Lelakabe, le sa tloaelehang •Ho hana hamore, khoholeho ea mobu, ho khojoa le ho khoroha ha ho thella | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤ 550ºC | •Flame, APS, e sa tloaelehang, Max.mocheso o sebetsang 815°C. • Apara thepa e thibang, e ka sebelisetsoang ho lokisa marake a tanka | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤800ºC | •Lelakabe, APS, Max.mocheso o sebetsang 980°C. • Ho fafatsa ka plasma ka ho itlama | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, e sa tloaelehang, Max.mocheso o sebetsang 980°C. • E sebetsa ho lokisoa ha mocheso o phahameng oa ho kopanya mocheso kapa likarolo tsa ho roala / tse sa sebetsoeng hantle | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | • Self bonding, coat e tloaelehileng e thata bakeng sa ho kenya kopo •E thata, e nang le khanyetso e ntle ea kutu le ts'ebetso ea ts'ebetso • E sebelisoa bakeng sa likarolo tsa mochine, setulo se nang le setulo le valve | |||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame,APS, irregular, Max.mocheso o sebetsang 650°C. •Bakeng sa litiiso tse silang, ho kenyeletsoa likarolo tsa tiiso tse suthehang, masale a tiisitsoeng a silang, lisebelisoa tse tlase tse hohlang. | ||||||||||||

Thomo ea rona ke ho fa basebelisi ba rona ba ho qetela le bareki ka thepa ea boleng bo holimo le e nkehang habobebe ea dijithale bakeng sa Factory For NiAl cladding powder, Lab ea rona joale ke "National Lab of diesel engine turbo technology", 'me re na le sehlopha sa R&D se nang le boiphihlelo le liteko tse felletseng. setsing.

Fektheri Bakeng saChina NiAl cladding phofo, Sepheo sa rona se latelang ke ho feta litebello tsa moreki e mong le e mong ka ho fana ka litšebeletso tse ntle tsa bareki, ho eketseha ha maemo le boleng bo boholo.Ka kakaretso, ntle le bareki ba rona ha re eo;ntle le bareki ba thabileng le ba khotsofetseng ka ho feletseng, re hlōleha.Re ntse re batla mabenkele a mangata, Drop ship.U lokela ho iteanya le rona haeba u khahloa ke thepa ea rona.Ke tšepa ho etsa khoebo le uena kaofela.Thomello ea boleng bo holimo le e potlakileng!